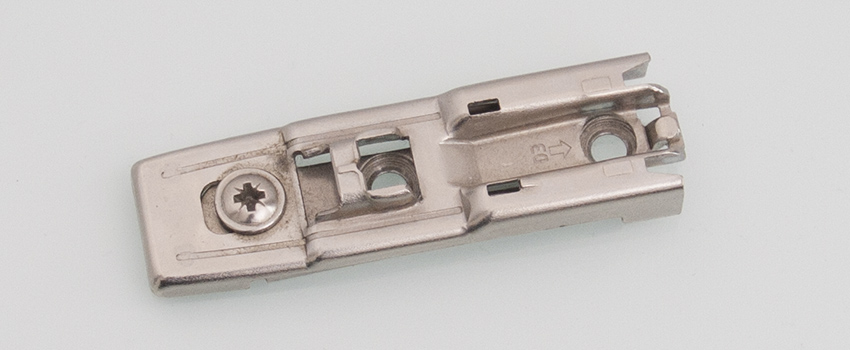

CD welding, fittings and hinges

Passive houses with excellent thermal insulation require accordingly insulated and therefore heavy doors and windows. These require secure locks and hinges, which reliably feed static and dynamic loads into frames and profiles.

If a 6 mm bolt is exposed to a shear load of max. 10 kN then the complete cross section must be welded. The CD process alone manages this, without loading the components with overly high process heat.

If not only a secure connection but also the aesthetics are important then clear traces of the welded connection are undesirable, a weld seam interferes with assembly, annealing colours must be arduously removed and insecure welds are dangerous. If such tasks can be resolved with a resistance welding process then significant cost advantages arise in comparison to laser welding for example.

If the pressure on the functional surfaces is too great or the sheet cross section is unable to withstand the forces on a permanent basis then it is only possible to improve the material characteristics. Innovative hardening processes constitute a very good solution approach here. However, components that are hardened or can be hardened are only suitable for welding to a limited degree. CD welding with CP technology offers a tried and tested solution here. It is possible to reliably overcome this challenge by welding with a main pulse and a subsequent tempering pulse.

In order to economically produce simple components and still protect them against corrosion, a suitably coated initial material is used. If welding is subsequently necessary, extremely low-heat and efficient processes are required. The transformed capacitor discharge with a high welding current pulse results in very short welding times and enables targeted heat application in the joining zone.