The focus lies on the joining technology

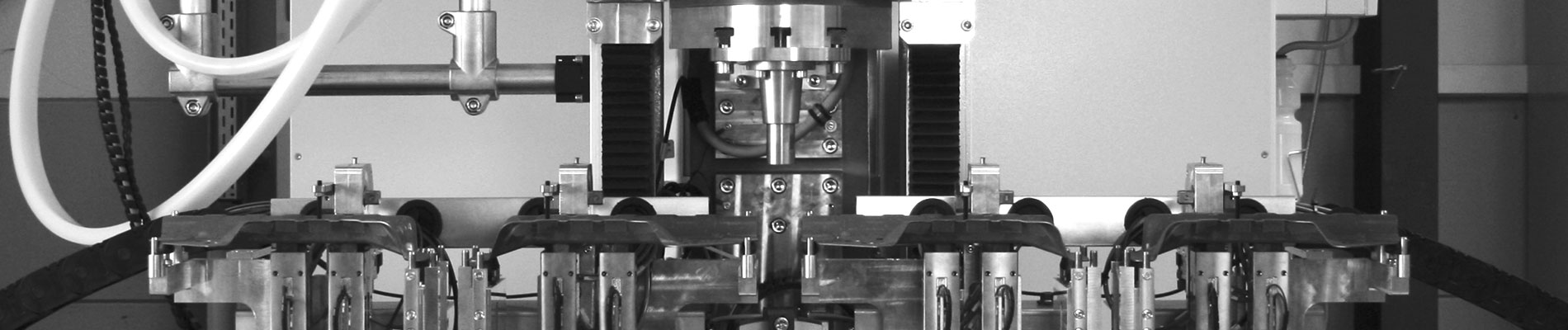

The use of the system technology for CD welding is determined by the joining task to be fulfilled. In order to satisfy the constantly increasing requirements placed on the welding process by new materials even more fully, Kapkon places even greater significance on the analysis/investigation of joining processes. As such, the joining technology test centre (FtVZ) in Oyten near Bremen opened its doors in December 2017.

In 2020 this center was moved to the company’s headquarter in Bad Salzuflen. The FtVZ is equipped with a modern laboratory for capacitor discharge welding, in which basic investigations are performed on focal topics of the HWH Group and analyses are carried out for the joining tasks of customers. Furthermore, interested parties are offered the opportunity of using the lab for their own test series.