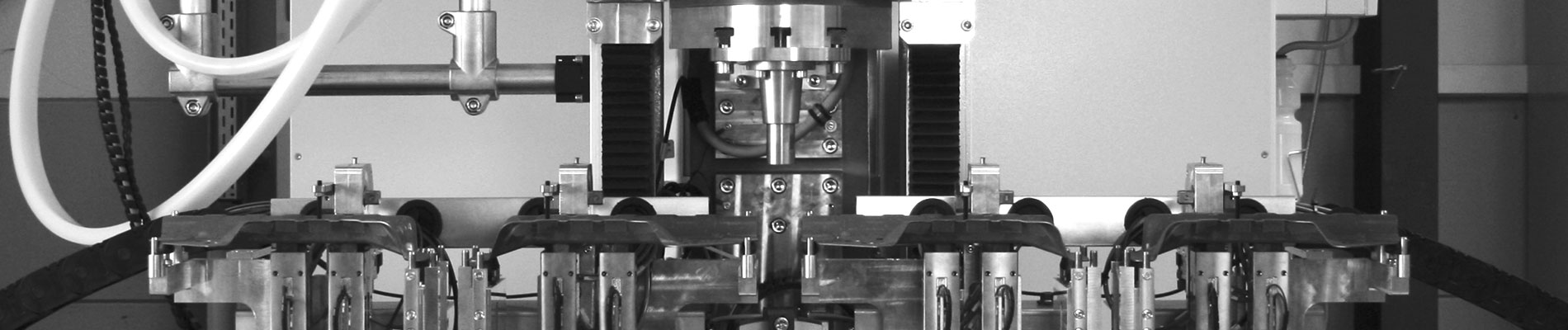

Capacitor discharge welding (CD welding) takes place with a very high, short-term surge current (up to 1 000 kA), which is supplied via a transformed capacitor discharge. This is a special form of projection welding, although it is also individually applied as resistance spot welding. With CD welding, the top and bottom electrodes press against the joining components with high contact forces (from 10 kN and significantly higher). Through the ignition of a thyristor, the charge of a capacitor bank is fed via a pulse transformer and on the secondary side via electrodes into the joining parts. The welding current heats the materials partially until close to their melting point, so that the parts are substance-to-substance bonded after cooling.

Significant advantages of CD welding are not only the short process time, but also the low electrical power input required, the high degree of efficiency and the low thermal load on the workpieces and the tools. The short-term and local heat application, which results in negligibly low heat dissipation into the basic material, facilitates the welding of mixed combinations of various materials, welding in thermally sensitive areas and the welding of greater thickness and cross-sectional variations. Furthermore, CD welding also permits the joining of materials with high electrical and thermal conductivity, such as aluminium, copper and brass. The reproducible discharge of the welding capacitor delivers high process reliability.

You can find further information on CD welding here.